China: The Latest Development In Plastic Mold Manufacturing

China is leading the way in plastic mold manufacturing because of its ability to produce high-quality, cost-effective plastic mold in large quantities. Read on for a breakdown of how China’s success is better for consumers and the industry alike!

What is the latest development in plastic mold manufacturing?

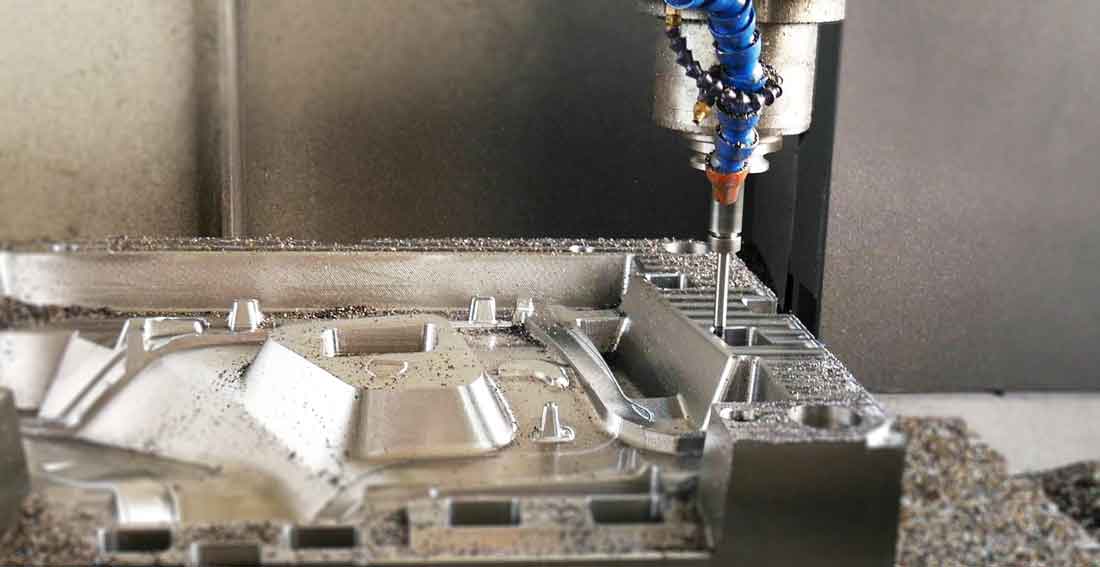

Plastic mold manufacturing is the process of making plastic objects by forming them from a liquid plastic material that is then solidified. The latest development in plastic mold manufacturing is the use of 3D printing technology.

3D printing is the process of creating an object from a digital data file. This technology uses a machine that deposits successive layers of material to create an object from a solid model.

This technology has many advantages over the traditional methods of China mold makers. First, it is faster and less expensive because there is no need to create a physical model first. Second, it is more accurate because the printer can create intricate details without having to build up the model layer by layer. Third, it is easier to recycle because 3D printing does not require the use of special materials or processes that can damage recyclable materials. Finally, it can be used to create products that are difficult or impossible to make using other methods, such as customized parts or medical implants.

History of the development of plastics in China

China has played a significant role in the development of plastics, as the country is home to some of the world’s top manufacturing facilities. The first plastics were made in China in 1894, and over the years, the country has become one of the world’s leading manufacturers of plastics. Today, China produces more than 30% of the world’s total output of plastic products.

One of the reasons why China has been so successful in manufacturing plastic products is its large population and its ability to rapidly industrialize. In 1950, when China was still a semi-feudal society, only 1% of its population was engaged in the industry. But by 1978, this figure had risen to 25%. Today, more than half of China’s population is employed in industry, which has helped make China one of the world’s leading economies.

China has also been able to take advantage of its abundant resources to develop its plastics industry. For example, China has huge reserves of coal and oil, which are necessary for the production of polyvinyl chloride (PVC) and other synthetic materials used in the manufacture of plastics.

How did China develop its own plastics industry?

China has been a world leader in the production of plastics since the 1950s. By the early 21st century, China had become the world’s largest producer of synthetic resins and plastics. The country’s manufacturing sector is now responsible for more than 20% of global output.

China’s plastics industry is based on two key pillars: domestic consumption and exports. Domestic demand is driven by a rising middle class, which needs to buy new products and services every day. The Chinese government has played a significant role in supporting the growth of the sector, through subsidies, tax breaks and other initiatives. The country also has a large pool of skilled workers, which has helped drive down costs.

China’s competitive advantage lies in its ability to produce high-quality plastic products at low costs. This has enabled Beijing to dominate the global market for synthetic resins and plastics. In fact, China accounts for more than 60% of global sales of these products.

China’s growing appetite for plastic goods is likely to boost demand for these materials over the next decade or so. In addition, Beijing is focusing on improving the performance of its infrastructure in order to support faster growth in industrial production.

Types of plastics made in China

China is the world’s leading producer of plastics, making over one-third of all the plastic produced in the world. The types of plastics made in China include:

-Polypropylene (PP)

-ABS

-Acrylic

-PVC

-PET

-Fiberglass

-Others

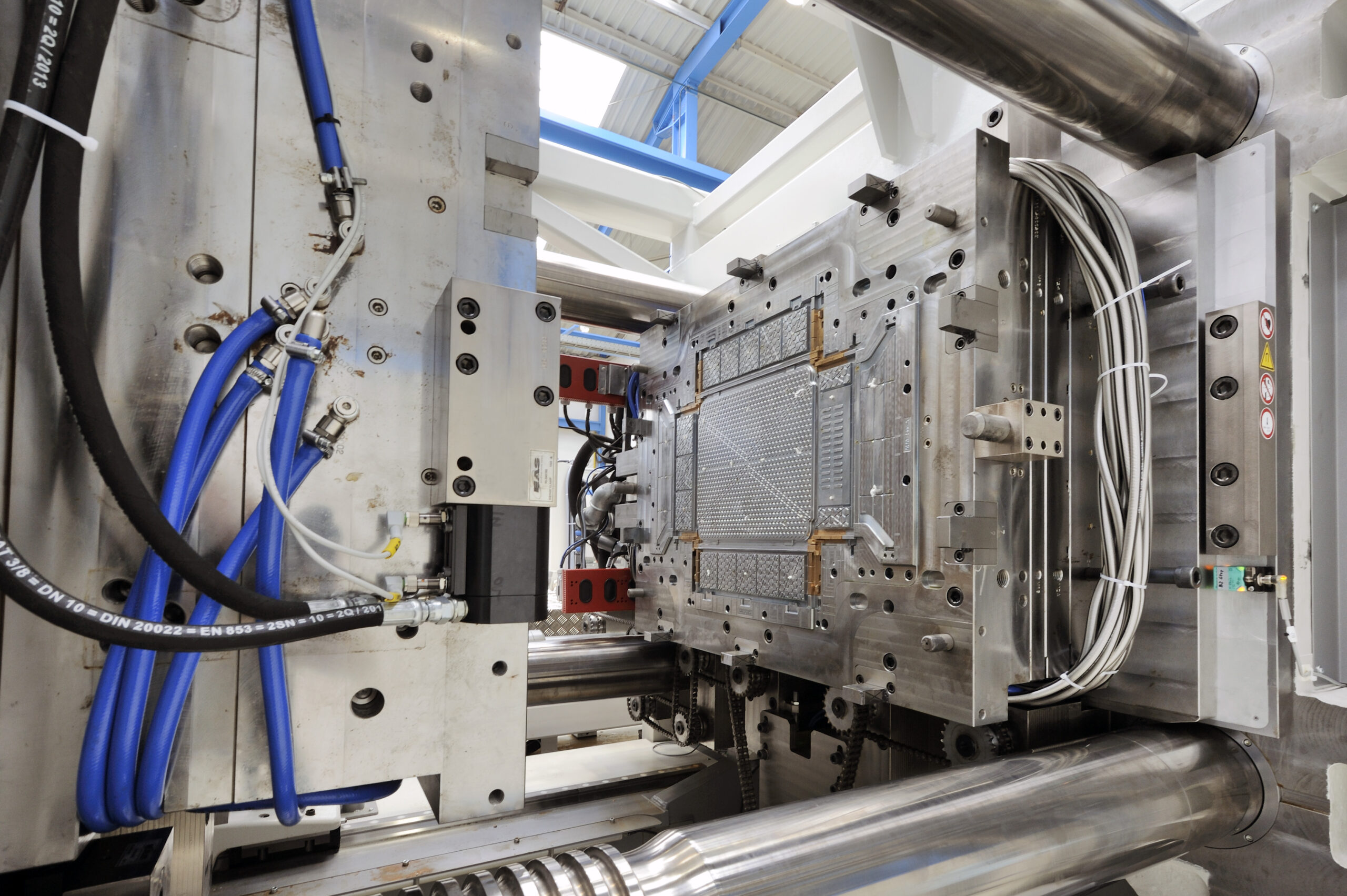

The production process for these types of plastics starts with raw materials, such as oil or gas. This raw material is then processed into plastic pellets and molded into products. Different types of molds are used to create different products, such as injection molding and extrusion molding. China’s manufacturing process is highly automated, which helps to reduce costs.

Wrapping Up

In this article, we will take a look at some of the latest developments in plastic mold manufacturing that are taking place in China. By understanding what is happening in China concerning plastics mold manufacturing you can better understand the implications these developments have on your business.