Unveiling the Secrets of Flow Meter: Navigating Fluid Dynamics

Flow meters, the unsung heroes of countless industries, hold the key to understanding the movement of fluids in pipelines and conduits. From industrial processes to everyday applications, these devices play a pivotal role in maintaining efficiency, conserving resources, and ensuring precision. In this exploration of flow meter, we delve into their science, types, applications, and the exciting future that lies ahead.

In a world where fluids – be it liquids or gases – are the lifeblood of industries and everyday activities, the accurate measurement of their flow becomes paramount. Imagine an oil refinery trying to optimize production, a water treatment plant managing distribution, or even your morning coffee machine delivering the perfect brew – all depend on the understanding and control of fluid movement.

The Science Behind Flow Measurement

Flow measurement is rooted in the principles of fluid dynamics, a complex realm where factors such as pressure, velocity, and volume intertwine. At its core is Bernoulli’s principle, which states that as the velocity of a fluid increases, its pressure decreases. This phenomenon forms the foundation of various flow measurement techniques, enabling us to quantify the behavior of fluids under diverse conditions.

Types of Flow Meters: A Closer Look

Flow meters come in a multitude of designs, each tailored to specific fluid characteristics and measurement requirements:

- Tapping into Pressure Differential: Orifice plates and Venturi tubes harness pressure differentials caused by constrictions to infer flow rates. These ingeniously simple devices slice through fluids, manipulating pressure changes into measurable quantities.

- Capturing Fluid Displacement: Positive displacement meters, employing gears or chambers, literally capture and measure the volume of fluid displaced. This method is ideal for viscous fluids and applications where precision is paramount.

- Harnessing Velocity for Precision: Turbine flow meters use fluid momentum to spin a turbine, translating rotational speed into flow rate. Electromagnetic flow meters employ magnetic fields to gauge fluid velocity accurately, regardless of fluid composition.

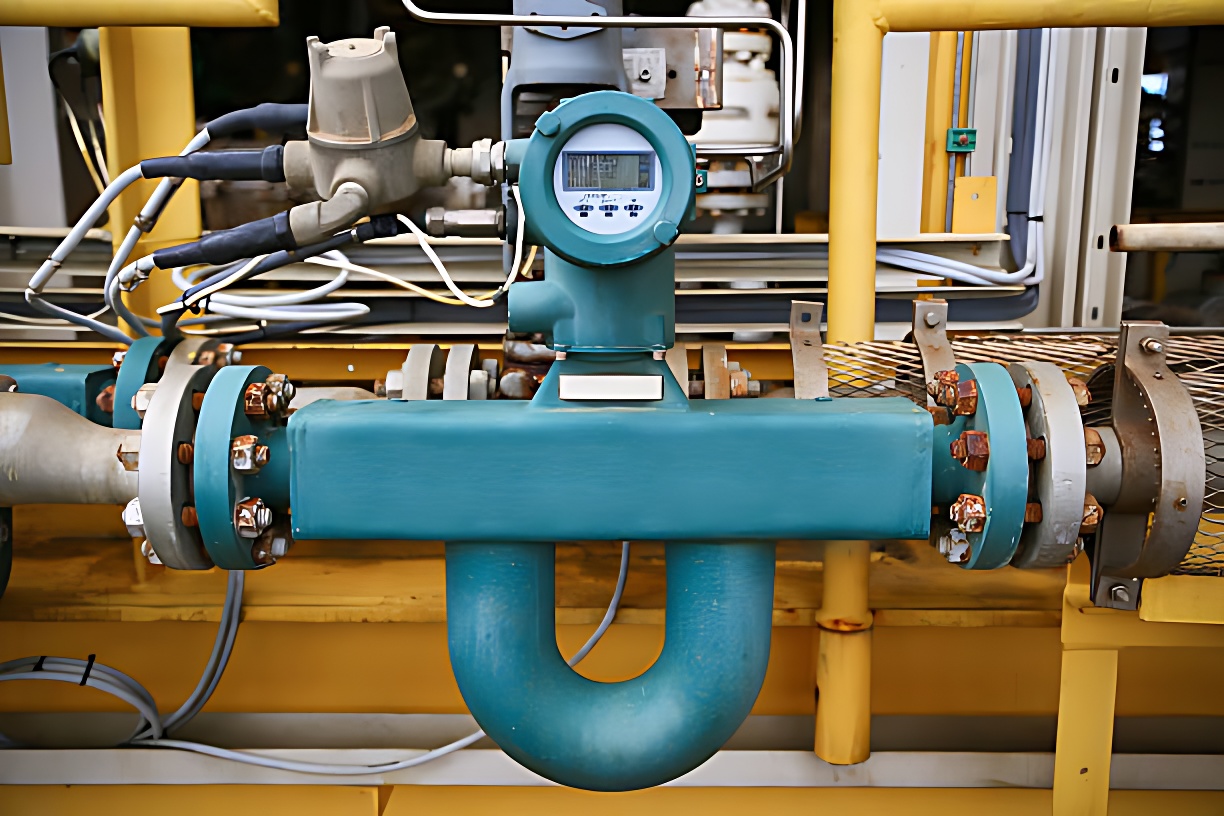

- Weighing Fluid Mass: Coriolis flow meters introduce a dance of vibration – a symphony that varies with mass flow rate. This method directly measures mass, making it a go-to for challenging applications involving gases or changing densities.

Selecting Your Flow Meter: Navigating the Choices

Choosing the right flow meter requires a meticulous assessment of various factors, from fluid properties to installation feasibility:

- Matching Fluid Personalities: Fluid type and composition influence the meter’s suitability and accuracy.

- Unraveling the Flow Rate Riddle: Understanding the expected flow rates, whether steady or variable, guides the meter selection.

- Pursuit of Precision: The accuracy and calibration requirements dictate the meter’s sophistication.

- Installation Ease and Challenges: Consideration of the available space, pipe size, and flow profile are crucial for effective installation.

- Maintenance: Regular maintenance and calibration are the lifelines of reliable measurements.

Applications: Flow Meters in Action

The versatility of flow meters transcends industries:

- Oil and Gas: In this vital sector, flow meters enable the accurate measurement of crude oil, refined products, and gases, driving operational efficiency and financial accuracy.

- H2O Matters: Flow meters ensure equitable water distribution, optimize treatment processes, and detect leaks, contributing to responsible water management.

- Mixing and Moving: In chemical processing, flow meters maintain precise ingredient ratios, optimize reactions, and ensure product quality.

- Food and Flavor: Flow meters are instrumental in maintaining consistent production quantities, adhering to strict regulations, and guaranteeing the taste and safety of consumable products.

- Medical Marvels: In healthcare, flow meters accurately dispense medications, oxygen, and other medical gases, playing a critical role in patient care.

Beyond Measurement: Advantages and Challenges

The advantages of flow meters go beyond measurement:

- Precision in Real-Time: Flow meters empower decision-making through real-time data, enabling prompt adjustments to optimize processes.

- Flow Optimization: By accurately measuring flow rates, industries can reduce waste, conserve resources, and cut operational costs.

- The Dance with Complex Fluids: Challenges arise when dealing with viscous, corrosive, or abrasive fluids, requiring specialized flow meters and careful maintenance.

Future Horizons: The Evolution of Flow Meters

As industries embrace digital transformation, flow meters are stepping into a new era:

- Smart Flow Meters: Digital sensors and connectivity enable real-time monitoring and data analysis for improved decision-making. These intelligent devices offer self-diagnostics, enabling predictive maintenance and minimizing downtime.

- Data-Driven Insights: Flow meters integrated with the Internet of Things (IoT) provide actionable insights for predictive maintenance and process optimization. The ability to remotely monitor and adjust flow rates based on real-time data paves the way for more efficient and responsive operations.

Expert Voices: Insights and Case Studies

Real-world success stories illuminate the potential of flow meters:

- Success Story: Revamping Industrial Efficiency: An industrial plant reduced energy consumption and increased productivity by implementing ultrasonic flow meters, pinpointing inefficiencies and enabling proactive adjustments.

- Unveiling Hidden Leaks: Case of Environmental Impact: In a water treatment facility, a magnetic flow meter detected a hidden leak, preventing thousands of gallons of water waste and underscoring the importance of early detection.

- Precision Redefined: Medical Flow Meter Innovations: Hospitals benefit from mass flow meters that ensure precise delivery of medications and gases, enhancing patient care while minimizing wastage.

Navigating Regulations: Standards and Compliance

Accuracy and safety are paramount in flow measurement:

- Charting International Flow Measurement Standards: Regulatory bodies like ISO set guidelines for flow meter accuracy, ensuring uniformity and reliability across industries.

- Ensuring Accuracy and Safety: Compliance with standards not only ensures accurate measurements but also prevents potential hazards and environmental concerns.

The Investment Equation: Cost, ROI, and Future Gains

Choosing the right flow meter involves a careful balance of costs and benefits:

- Balancing the Initial Cost with Long-Term Benefits: While high-precision flow meters may come with an upfront investment, the long-term savings in resource optimization and reduced downtime often outweigh the initial expense.

- Cost-Efficiency in the Age of Sustainable Practices: In today’s sustainability-focused landscape, flow meters contribute to resource conservation and align with eco-friendly practices.

Conclusion: Flowing Towards a Fluid Future

Flow meters, though often unseen, are the unsung heroes that underpin industries and modern conveniences alike. From powering your car with accurately measured fuel to ensuring safe medication delivery in hospitals, their impact is pervasive and profound.

Flow Meters as the Silent Heroes of Industry: In a world where precise measurements drive progress, flow meters provide the crucial data that enables industries to innovate and optimize.

Embracing Innovation for Better Flow Management: As technology advances, smart flow meters bring real-time insights and predictive capabilities, further enhancing operational efficiency and cost-effectiveness.

Appreciating Fluid Dynamics in Every Drop: The intricate dance of fluid dynamics, as captured by flow meters, continues to shape our world, from the grandest industrial processes to the tiniest everyday interactions.

In the end, flow meters serve as our guides through the intricate currents of fluid dynamics, offering insights that empower industries to move forward with precision, efficiency, and a firm eye on the future.