The Importance Of A Plastic Moisture Analyzer

Whether for incoming inspection, or in-process control, a Plastic moisture analyzer is an indispensable tool for companies involved in producing quality products using injection molding. It helps ensure that resins are dried to the proper specification. In order to measure the moisture of a plastic resin accurately, it must be free from other volatiles such as air and oil. The ideal instrument should also be capable of measuring very low moisture levels.

Accuracy

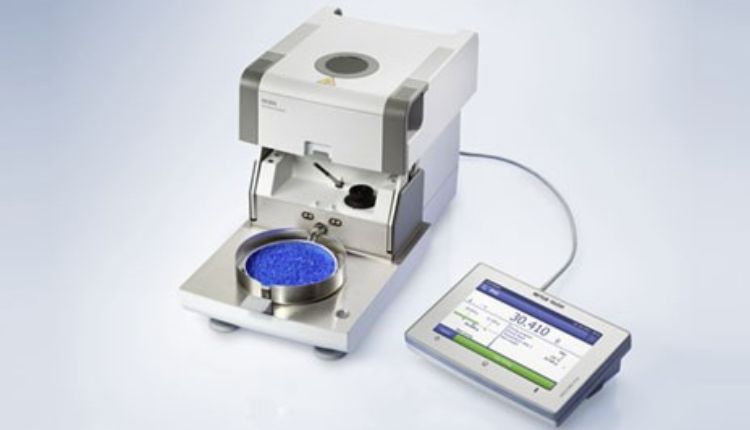

Moisture content is one of the most critical factors in the quality of plastic products. It can affect the processing and final product appearance and properties. Most plastics are hydroscopic, meaning that they readily absorb atmospheric moisture. Hence, the raw materials must be dried prior to processing. To determine the moisture content of plastics, you can use a gravimetric moisture analyzer such as the MB120 from OHAUS. This instrument consists of a sensitive balance and a heated oven. The sample is spread on the test pan and the mass before and after heating are compared to determine the percentage of weight loss due to water vapor.

When choosing a plastic moisture analyzer, look for a model that offers high accuracy. This will ensure that your results are accurate, preventing the need for expensive rework. Additionally, it will enable you to meet production deadlines and ensure that your products are of high quality. Look for a model that can accurately measure moisture in a variety of samples, including powders and granules, and also offers flexibility with test methods such as capacitance, microwave, or near-infrared.

Reliability

When working with extremely dry substances like plastic resin, the smallest differences in moisture content must be reliably measured. This is why you should only use a high-quality Plastic moisture analyzer dscbalances.com in your production environment. Injection molding firms often deal with a variety of different resin formulations. Each type of resin has its own unique test method and performance specifications. Moisture content is a critical factor in the process and a failure to control this can result in splaying and other processing problems.

A good option is the Radwag PMC 50 from Nevada Weighing, a quality moisture balance that is designed specifically for very dry samples and materials. It features a flexible halogen heating source and offers 0.1 milligram accuracy paired with 0.001% readability, making it ideal for working with sensitive samples. It also has five auto-stop functions to better establish testing parameters or keep a run going without interruption. The PMC 50 is backed by a 2-year manufacturer warranty.

Ease Of Use

Moisture analysis of plastic resin is critical to quality control for companies involved in injection molding. Resin shipped from a supplier may have the specified moisture content, but processing conditions in an injection molding company’s plant can raise or lower that amount. An improperly calibrated moisture balance could result in an inferior finished product. A good moisture analyzer can simplify and speed up this important task. An instrument that uses a method such as capacitance, microwave, or near-infrared technology is ideal for plastics. Some models can even perform multiple measurements simultaneously to save time and money.

A professional moisture analyzer from Mettler-Toledo offers USB, Ethernet and WLAN connectivity for easy data transfer to a computer or network printer. These instruments also feature a new, simple to use procedure that automatically normalizes for ambient conditions with SmartCal. This helps to ensure reliable and accurate moisture measurements every time. This means less time in the lab and more time in the production process.

Flexibility

Turning piles of recycled plastic into new items is an intricate process. It involves reducing plastic to chips, drying the chips, making them into granules, and then molding the granules into new products. The entire operation must be carefully monitored and controlled to avoid waste and poor quality.

Injection molding companies rely on a plastic moisture analyzer to ensure that their resins are within specifications before they enter the molders’ hoppers. These moisture analyzers use the loss of weight method to determine moisture and can be a great help in keeping production on track.

A plastic chip, granule, or pellet moisture analyzer gives you instant, non-contact measurements of the product. It lets you adjust the dryer performance and prevents waste, saving money on energy bills and raw materials. It also reduces start-up and down times. It’s easy to integrate the device with your plant control system via Ethernet, USB, or RS485 Modbus. It can even be used with the Moretto MOWIS supervising system.

Conclusion

Moisture is a key issue for plastic production processes. Without proper moisture control, nozzle drool or silver streaks can occur along with poor physical properties. Sartorius’ Aquatrac Station is a high-end moisture analyzer that’s perfect for plastic resins. It allows for complete sample drying in only 10-20 minutes and reads to 0.0001 g (0.001%). It is an ideal alternative to Karl Fischer titration.