CNC milling explained

CNC milling is a technology that has been used in manufacturing for many years. But what is it, and what are its benefits? In this article, we will answer those questions and more. We will also discuss what types of projects CNC milling best suits.

So, if you’re curious about this technology, keep reading!

What is CNC milling?

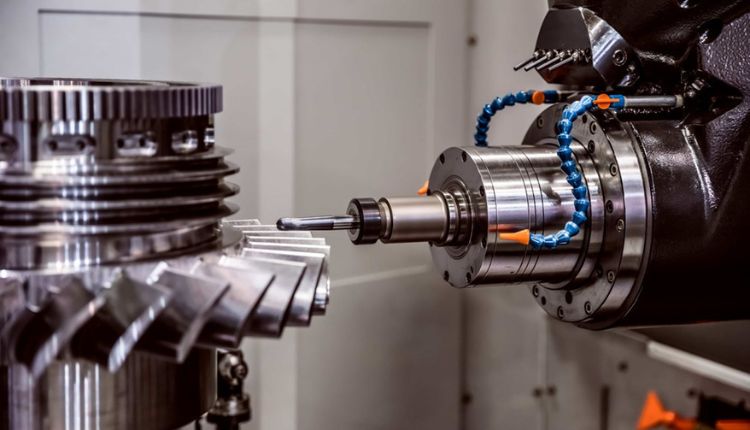

CNC milling is a type of computer-aided machining. It uses computer numeric control to automate the process of milling or cutting metal and other materials. The benefits of CNC milling include increased accuracy, improved productivity, and greater flexibility. With CNC milling, operators can take advantage of advanced features such as 3D cutting and multi-axis machining.

These features allow them to create parts and products with greater precision and detail than ever before. In addition, CNC milling can produce large quantities of parts quickly and efficiently. As a result, it is an essential tool for manufacturers who need to meet the demands of a rapidly changing marketplace.

How does a CNC mill work, and what materials can it process?

The milling process can be used to create exact and intricate shapes, and it can also be used to rout out large areas of material. CNC mills are typically used to work with metal, wood, and plastic, but they can also work with various other materials.

To operate a CNC mill, the operator will first input the desired dimensions and shape into the computer. The computer will then generate a toolpath to guide the cutting tool along the desired path. Once the toolpath has been generated, the operator will start the machine and let it run until the job is complete.

CNC mills are incredibly versatile machines that can be used for various applications.

What industries use CNC milling technology?

CNC milling technology is used in a wide variety of industries, from automobile manufacturing to the production of medical implants. At a CNC milling service, a computer-controlled cutting tool removes material from a workpiece to create a final product. This method can be used to create complex three-dimensional shapes with high accuracy.

Some examples of products created using CNC milling include automobile engine parts, aeroplane wings, and surgical implants. As the accuracy and versatility of this technology continue to improve, even more industries will likely begin to use CNC milling.

How much does a CNC mill cost?

A CNC is often used in manufacturing and prototyping applications. The cost of a CNC mill can vary depending on your required features and capabilities.

If you are interested in acquiring a CNC mill for your business or home workshop, there are a few things that you will need to take into consideration. Firstly, you will need to decide what materials you will be milling. This will help to determine the features and specifications that you will need. Secondly, you will need to consider your budget and the level of investment that you are willing to make.

Once you have considered these factors, you can begin to research the different types of CNC mills available on the market.

Are there any safety concerns to be aware of when using a CNC milling machine?

CNC milling machines must be used with care like any power tool to avoid injury or damage. There are several safety concerns to be aware of when using a CNC milling machine:

- Wear protective gear, including safety glasses or a face shield, gloves, and hearing protection.

- Be sure to secure the workpiece before starting the machine.

- Never try to remove chips or debris while the machine is running.

- Keep your hands and clothing away from moving parts.

- Always follow the manufacturer’s instructions when using the machine.

Taking these precautions can help ensure a safe experience when using a CNC milling machine.

Finally, here are some tips on getting started with CNC milling – including advice on choosing the right software and setting up your workspace for optimal results.

If you’re considering using a CNC mill for the first time, there are a few factors to bear in mind to guarantee an efficient process:

- Choose the right software for your needs. There are several fantastic alternatives on the market, but choose one compatible with your equipment and includes all the functions you need.

- Set up your workspace for optimal results. This means having enough space to move around comfortably and having all the necessary tools within reach.

- If you follow these simple instructions, you’ll be an expert in CNC milling in no time!

Final thoughts

CNC milling is a process that you can use to create various objects from metal, plastic, and other materials. The three-dimensional objects are created by removing material from a block of stock using computer-controlled cutting tools.

To produce high-quality products, it is crucial to understand the basics of CNC milling. By following the steps in this article, you should be able to create accurate parts with tight tolerances using a CNC milling machine.